The stability performance of Anmei PBT low-shrinkage masterbatch in over-length shrinkage and post-shrinkage of large-wall thickness casing proved by tests

In the operation and maintenance of optical cables, splicing (fusion) is usually performed by identifying the color of optical cables. Different optical cables, different casings, and different optical fibers can be distinguished by color. Polybutylene terephthalate (PBT) is the main material for fiber optic sleeves. In the production process of the secondary sleeve, the PBT is formed into a loose tube by extrusion molding, which provides protection for the optical fiber in the sleeve. The excess length of the optical fiber or the optical fiber ribbon in the sleeve is the most important parameter in the secondary sheathing process, which largely determines the main performance of the optical fiber loss, cable stretching, and temperature characteristics.

As a polymer material, PBT is in a semi-crystalline state in the extrusion stage, and it has a tendency to post-crystallization after extrusion. In addition, further crystallization occurs with changes in temperature and time. The post-crystallization causes the post-shrinkage of the PBT sleeve, which further shortens the length of the sleeve and increases the excess length of the optical fiber in the sleeve. This uncontrolled change in excess length should be kept to a minimum during casing fabrication.

Post shrinkage is an inherent property of PBT materials. The addition of masterbatch to PBT not only colorizes the casing but also acts as a nucleating agent in the extrusion process, thereby affecting the crystallization process and crystallinity of PBT. Different manufacturers and different colors of masterbatch have different effects on the crystallinity and post-shrinkage of PBT due to differences in carrier resins or pigments, so the stability of the remaining length of the sleeve varies according to the color.

1. Test and Analysis

1.1 Test requirements:

The surface of the debugged casing is smooth and round, full of oil, the geometric dimensions meet the requirements, and the excess length and post-shrinkage meet the requirements of 0.3±0.3‰.

1.2 Test method:

In order to verify that the shrinkage effect of the Anmei color masterbatch on the PBT large-wall thickness loose tube is within the required range, we selected three styles of color masterbatches for comparative testing from well-known brands. Detect the current excess length and the excess length of the 1st day, the 3rd day, and the 7th day of each color masterbatch used for extruding the loose tube.

1.3 The test parameters are shown in the following table:

Test environment | Room temperature℃ | 22℃ | Relative humidity % | 45% | |

Product specifications | 2.0-6 cores (wall thickness 0.4mm) | Production machine | #TS | ||

Main raw materials | Material name | Material manufacturers | Usage amount | ||

PBT | Factory A、FactoryJ-Q04、FactoryJ-Q01、Factory Y | 50kg | |||

Masterbatch① | Factory J | 15kg | |||

Masterbatch② | ANMEI | 15KG | |||

Masterbatch③ | Factory Y | 15KG | |||

Fiber cream | Factory XCL | 50kg | |||

Fiber | HT Fiber | 20km | |||

工装模具 | The mold sleeve 8.8 and mold core 4.4/5.2 | ||||

工艺参数 | Extrusion temperature: 240 250 250 250 250 250 250 250℃;Drying temperature:100℃; | ||||

1.4 Testing procedure

Using Factory J or Factory Y PBT to verify the performance of Anmei (low shrinkage), Factory J n and Factory Y color masterbatch, and the debugging conditions are as follows:

Brand Color | Specifications | Extrusion speed/E | grease speed/ J | Production speed m/min | Masterbatch speed | Main raction laps | Auxiliary traction tension/N | Take-up tension/N | Water T/℃ | Debug casing appearance | Outer diameter /mm | Wall thickness mm |

Blue | 2.0-6 cores (0.4 wall thickness) | 39.5 | 7.3 | 200 | 0.5 (Factory Y 0.3-0.5) | 12 | 8 | 9 | 28 28 22 | Good | 1.99-2.07 | 0.4 |

Orange | 40 | 7.3 | 1.99-2.06 | |||||||||

Green | 39.5 | 7.2 | 1.98-2.07 | |||||||||

Brown | 40 | 7.3 | 1.99-2.06 | |||||||||

Gray | 39.5 | 7.3 | 1.98-2.07 | |||||||||

White | 39.5 | 7.2 | 1.98-2.07 | |||||||||

Red | 40 | 7.3 | 1.98-2.07 | |||||||||

Black | 40 | 7.3 | 1.99-2.06 | |||||||||

Yellow | 40 | 7.3 | 1.98-2.06 | |||||||||

Purple | 39.5 | 7.3 | 1.98-2.07 | |||||||||

Pink | 39.5 | 7.2 | 1.98-2.07 | |||||||||

cyan-blue | 40 | 7.3 | 1.99-2.06 |

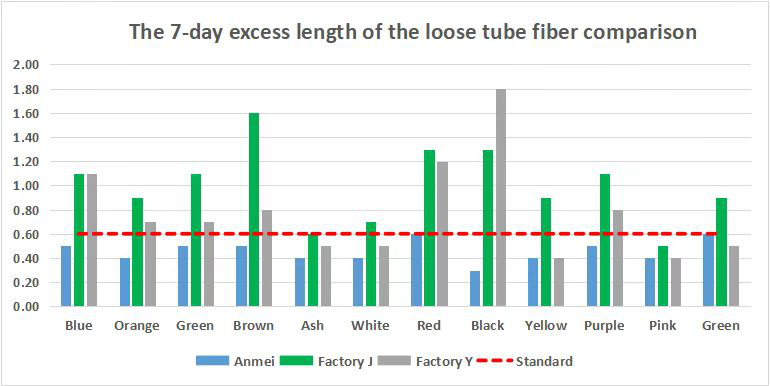

The 7-day excess length distribution of the loose tube optical fiber made by different color masterbatches is as follows according to the analysis of the test data.

The 7-day excess length of the loose tube fiber comparison

1.5 Test Results:

The changing trend of Anmei (low shrinkage) color masterbatch over 7 days is shown in the figure below. The casings debugged by Anmei low shrinkage 12 (Munsell) color masterbatches have a good appearance, full oil filling, outer diameter, wall thickness, etc. The size is good, and the color and excess length meet the requirements.

The changing trend of the 7-day excess length of Factory J masterbatch is shown in the figure below. The casings debugged by the 12 color masterbatches of Factory J have a good appearance, full oil filling, good geometric dimensions such as outer diameter and wall thickness, and the excess length is too large.

The changing trend of Yingmao masterbatch's 7-day surplus length is shown in the figure below. The casings debugged by Facoty Y 12 color masterbatches have a good appearance, full oil filling, good geometric dimensions such as outer diameter and wall thickness, and the remaining length is blue and black. , the red is too large, the rest of the color is slightly larger, and the consistency of the color is general.

Due to the differences and defects of the material itself, the loose tube fiber excess length will be unstable, and the effect of color masterbatch on the excess length is mainly because the color masterbatch will interfere with the crystallinity of PBT, resulting in increased post-shrinkage of PBT. By testing and comparing the excess length of loose tube optical fibers produced by 12 different formula color masterbatches of three similar products, Anmei color masterbatch (low shrinkage) has played a better performance than other manufacturers in a loose tube with large wall thickness. The 7-day surplus length was stable at 0.3±0.3‰. Anmei will continue to improve the color masterbatch formulation to help optical cable manufacturing companies further improve the crystallinity and impact strength of the material while reducing production costs.

In conclusion

Therefore, in production, the mixing ratio should be strictly controlled to ensure that the color of the casing is consistent, and the process is fine-tuned when producing casings of different colors to improve the stability of the extra length of the casing.